It is a highly competitive industry, with tightly regulated quality standards, and significant emphasis placed on innovation. This in turn necessitates manufacturing facilities of the highest standard for producers operating within the sector.

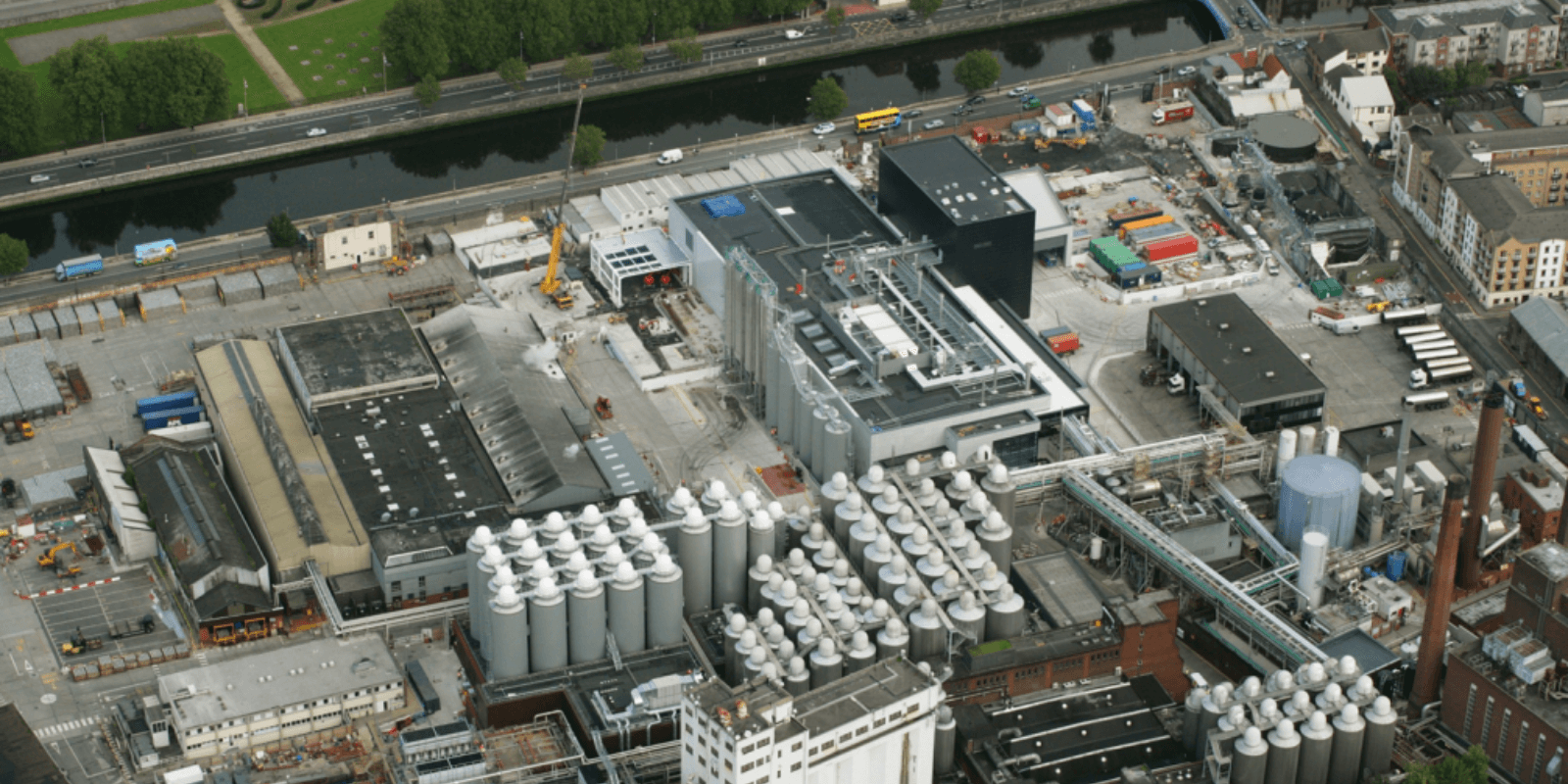

One of Linesight’s landmark projects in the sector was Diageo’s Brewhouse 4 at the world-famous St. James’s Gate Brewery in Dublin. The facility is one of the most technologically advanced breweries in the world, and was awarded the highest achievable rankings in terms of sustainability. The project’s success is largely attributable to the client and project team’s adoption of innovation throughout the project. Below, we look at the key innovations associated with Brewhouse 4, which can be applied to other projects within the sector globally.

As only the fourth brewhouse to be built on the St James’s Gate site in Dublin during its 255 year history, Brewhouse 4 presented a unique challenge for the Client and design team, as brewing never stopped during construction, such is the demand for the ‘black stuff’ worldwide.

Linesight was appointed to support Diageo on Cost and Procurement for the delivery of the new brewhouse and fermentation block at St. James's Gate. Completed in summer 2014, it was one of the largest construction projects to take place in Dublin in recent years, and created in excess of 1,000 construction jobs.

The purpose of the ‘Zero Harm Culture’ model was to create, a consistent proactive culture for safety across all operations. By measuring, understanding and actively developing the prevailing safety culture on Brewhouse 4, it fostered a set of shared values leading to an ultimate vision that ‘Everyone goes home safe, every day, everywhere’.

‘Zero Harm’ is based on four pillars: prevention, culture, compliance and capability. It required a partnership between individual employees, managers, and the business as a whole to achieve the objectives of each pillar.

The result was that the accident frequency rate was at one tenth of the industry average on Brewhouse 4, which is a remarkable achievement.

The ‘Zero Defects’ program was followed from the start, with Diageo taking from the validation process used by the pharmaceutical industry to ensure zero defects. The process starts with user requirements specification, followed by design qualification. The design is then checked against the user requirements and when installed, an installation qualification is followed to confirm that it has been installed in accordance with that design.

A sample room in an adjacent building became the ‘zero defect’ room where live mock-ups of all of the key elements were constructed. This room had three functions; it got the contractor to achieve what was required, it showed the client what they were getting and also served to train contractors as to what was needed. The zero defect system allowed all parties to walk away from the project at completion without the need for costly return visits.

An extremely tight deadline of 14 months called for efficient and effective strategic thinking.

Some of the areas in which this was particularly successful included:

Linesight supported Diageo with the Management of the budget. It was important that the project was adaptable to changes in scope as works progressed. Linesight had a full-time change manager on the project. The Change Manager’s key task was to support Diageo to ensure that no additional change to quality, cost or program was allowable without a change order signed by Diageo in advance.

This was a highly successful strategy, and gave Diageo full oversight of the decision-making process.

Other significant innovations in this area included:

Brewhouse 4 ultimately achieved LEED Platinum and BREEAM Outstanding status, the highest achievable rankings. The process involved full engagement with United States Green Building Council (USGBC) and Building Research Establishment (BRE).

The building itself is carbon neutral, the first and only non-domestic building in the Republic of Ireland to achieve the top Building Energy Rating (BER), A1.

The team adopted the Energy Efficient Design (EED) methodology to design, construct and manage the project, in order to achieve minimum energy consumption, and it was the key to reducing energy usage during the operational phase. In turn, capital cost savings were achieved in both utilities and processes, while CO2 emissions were reduced significantly.

The very high score in energy credit count, combined with other sustainability initiatives, contributed to the LEED Platinum Certificate and the BREEAM Outstanding Certificate. There were also many other credits that were achieved through the commitment of the design team and construction team.

The main highlights were;

Diageo drove innovation and hired a top-class team for this project. It was delivered on budget and on time, and it is one of the most technologically advanced and environmentally sustainable breweries in the world. The Linesight team was awarded individual medals of recognition following the completion of the project by Diageo, to reflect its exemplary performance. Many of the innovations and insights from the Diageo project can be drawn upon for future Food and Beverage developments, with this facility having been recognized as exceptional and industry-leading.

For further information on this project please contact Stephen Ashe, on stephen.ashe@linesight.com or +353(1) 6614711.

Share

Related Insights